Assistant Professor Wanyuan Gui

Keywords:Structural materials

Contact:guiwy@ustb.edu.cn

Researches

Wanyuan Gui is a structure materials-worker who working in the fields of High-temperature alloys, surface and interface systems. He received a PhD in Materials Science and Engineering from University of Science and Technology Beijing (USTB) in 2019. Now he works at National Center for Materials Service Safety (NCMS) of USTB to be a research assistant. He is interested in the mechanism of interaction between phase transformation and pore formation of TiAl-based micro-/nano-filtration membrane, failure mechanism of TiAl-based porous materials in extreme/multi-factor coupling environment, and alloys surface/interface corrosion and mechanical properties fabricated by laser cladding and additive manufacturing.

l Main Projects

Project 1:“National Natural Science Foundation of China”, “Mechanism of interaction between phase transformation and pore formation of novel high Nb-TiAl-based porous nanocomposite”, NO. 52101070, 300000 RMB, 2022-2024”.

Project 2:“Ministry of Science and Technology”, “Key Technologies for High Quality TiAl Alloy Powder Preparation and 3D Printing”, NO. 2021YFB3700500, 16500000 RMB, 2021-2025”.

Project 3:“Fundamental Research Funds for the Central Universities”, “Fracture mechanism of Ni-based alloys coating fabricated on low alloy steel by ultra-high-speed laser cladding”, NO. FRF-TP-19-080A1, 100000 RMB, 2019-2021.

Project 4:“China Postdoctoral Science Foundation”, “Failure mechanism of TiAl-based porous materials in extreme/multi-factor coupling environment”, No. 2019M660452, 80000 RMB, 2019-2020.

l Main Contributions

Contribution 1:We proposed a novel strategy for fabricating porous composite microfiltration membrane with 3D reticular architectures by combining diffusion forming and chemical reaction forming technologies. The 3D reticular architectures with Micro/Nano dual-scaled porous pores on cell walls of porous framework is optimized by employing 4 wt.% ZrO2 nanoparticles as Nano pore-forming agent. An ultra-high PM removal efficiency (99. 98% for PM5-10, 99.58% for PM2.5-5, 99.23% for PM1-2.5, 98.51% for PM0.5-1, 91.36% for PM0.3-0.5 and 79.66% for PM<0.3, respectively).

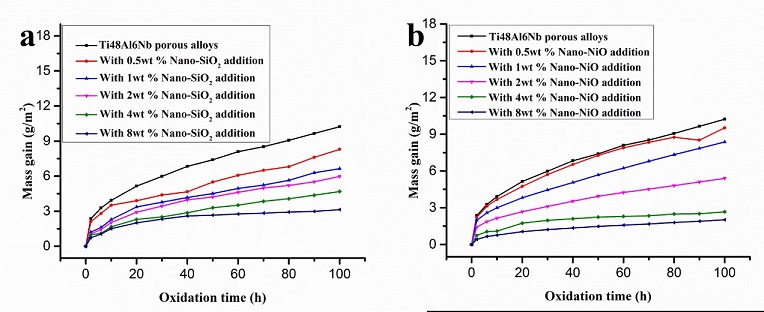

Contribution 2:Given that corrosion and oxidation have been two key challenges for the porous materials application under rigorous conditions. By manipulating an oxide nanoparticles chemical reaction of with Ti, Al, and Nb powders formation of porous composite. The excellent high-temperature oxidation resistance can be simultaneously achieved from the unique structure, demonstrating great potential for applications in environment related fields where highly effective high-temperature filtration is required.

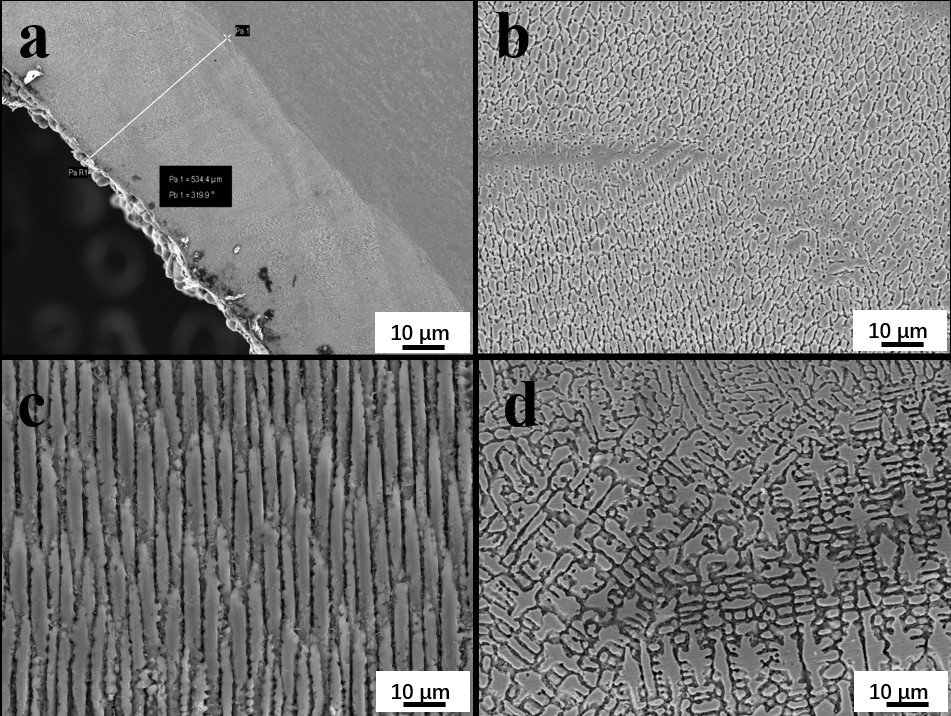

Contribution 3:Here, a high-speed laser deposition technique was used to successfully deposit Inconel 625 coatings on Q245R steel with dilution rate less than 2.6% at a cladding speed of 5 m/min. From Fig. 3a, it can be found that the Inconel 625 coatings with the thickness of about 534.4 μm exhibit a uniform dense structure with small amounts of particulate matter distributed on the surface of the Inconel 625 coatings. The high growth rate results in a low-to-moderate G/R ratio and pushes the microstructure towards a cellular structure appear in the bottom of the coating, as shown in Fig. 3(b). From Fig. 3(c) and 3(d), it can be found that the columnar and the equiaxial dendrites appear in the middle and top of the coating, respectively. Compared to the bottom part of the coating, the rest parts of coating have higher solidification rate (R) and moderate temperature gradients due to the fact that the Inconel 625 coatings experiences a repetitious remelt (overlapping: 80%). Thus, the columnar dendrites are observed at the middle zone of coating. There are two reasons for promoting the formation of equiaxed dendrites at the top of coating. On the one hand, the top zone of coating was exposed to the air and thus the big cooling rate (undercooling) of the top zone, which promotes the formation of equiaxed dendrites. On the other hand, local microsegregation lowers the melting point and may increase the likelihood for additional nucleation ahead of the dendritic front and inhibits the growth of columnar crystals.

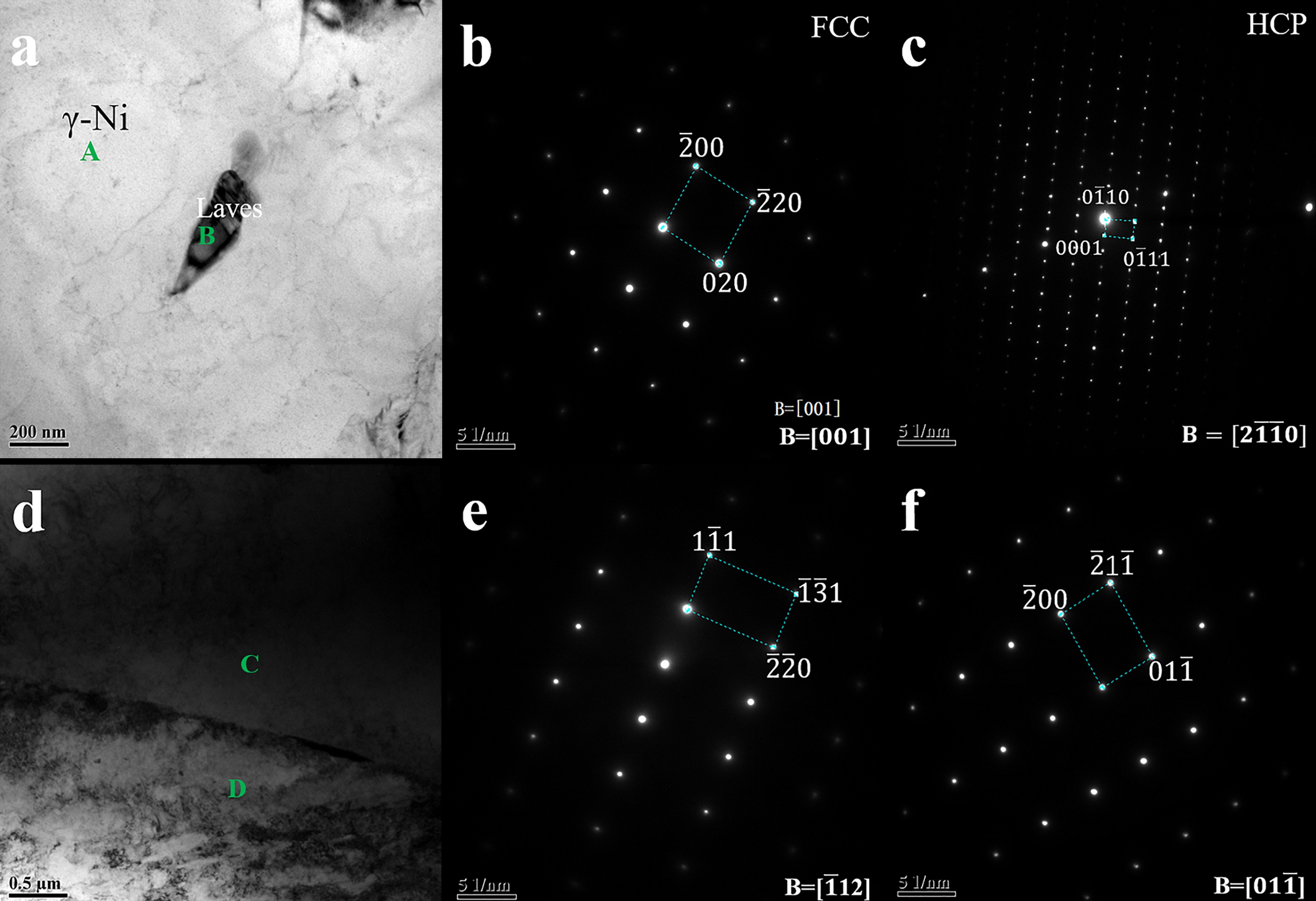

Phase identification for Inconel 625 coating was carried out by using TEM and the results are shown in Fig. 4. Fig. 4a shows the bright field image for an area with coexisting phases. Figs. 4b and 4c display the selected area diffraction patterns for the phase A and phase B in Fig. 4(a), respectively. As shown in Fig. 4b and 4c, the phases A and B shows the characteristics of γ-Ni phase with FCC structure and lavas phase with HCP structure. The chemical composition of lavas phase (phase B) was analyzed by EDS and the results are listed in Table 1. From Table 1, it can be found that the laves phase is rich in Nb and Mo. Fig. 4d shows the bright field image for an area with the interface between Inconel 625 coatings and Q245R steel substrate. Figs. 4e and 4f display the selected area diffraction patterns for the phase C and phase D in Fig. 4d, respectively. As shown in the phases C and D shows the characteristics of α-Fe phase with BCC structure and γ-Ni phase with FCC structure.

Table 1. EDS results of lavas phase

Element | Weight % | Atomic % | Correction | Uncert. % | k-Factor |

N | 4.85 | 24.24 | 0.16 | 0.28 | 3.536 |

Cr | 5.19 | 6.98 | 0.09 | 0.99 | 1.268 |

Ni | 2.63 | 3.14 | 0.07 | 0.99 | 1.453 |

Nb | 81.57 | 61.43 | 0.64 | 0.99 | 3.714 |

Mo | 5.74 | 4.18 | 0.17 | 0.98 | 4.047 |

l Publications

1. Y H Ding, W Y Gui (通讯作者), B X Nie, W Y Bi, C Zhong, Y P Xue, B L Luan. Elimination of elemental segregation by high-speed laser remelting for ultra-high-speed laser cladding Inconel 625 coatings. Journal of Materials Research and Technology, 2023, 24: 4118-4129.

2. K Fu, C Zhong, L Zhang, X M Wang, B X Nie, Y P Xue, W Y Gui (通讯作者), B L Luan. Effect of multiple thermal cycling on the microstructure and microhardness of Inconel 625 by high-speed laser cladding. Journal of Materials Research and Technology, 2023, 24: 1093-1107.

3. B X Nie, Y P Xue, X M Wang, Y H Ding, K Fu, C Zhong, W Y Gui (通讯作者), B L Luan. On the elemental segregation and melt flow behavior of pure copper laser cladding. Surface and Coatings Technology, 2023, 452: 129085.

4. Y H Qu, X M Sun, W Y Gui, R G Li, Z H Nie, Z Y Gao, W Cai, Y Ren, Y D Wang, D Y Cong. Complete and reversible magnetostructural transition driven by low magnetic field in multiferroic NiCoMnIn alloys. Acta Materialia, 2023, 243: 118535.

5. T F Yu, Y P Xue, W Y Gui, M Zheng, B L Luan. A new understanding on titanium coloration-variation of external stimuli and in-depth mechanism analysis. Surface and Coatings Technology, 2022, 450: 128999.

6. Y H Ding, W Y Bi, C Zhong, T Wu, W Y Gui (通讯作者). A Comparative Study on Microstructure and Properties of Ultra-High-Speed Laser Cladding and Traditional Laser Cladding of Inconel625 Coatings. Materials, 2022, 15(18): 6400.

7. T Wu, Y X Chen, B Lin, L T Yu, W Y Gui (通讯作者), J H Li, Y Wu, D W Zeng. Effects of WC on the Microstructure, Wear and Corrosion Resistance of Laser-Deposited CoCrFeNi High Entropy Alloy Coatings. Coatings, 2022, 12(7): 985.

8. W Y Gui, Y H Qu, Y X Cao, Y Z Zhao, C X Liu, Q Zhou, J Chen, Y H Liu. The effect of Tb substitution for Ni on microstructure, martensitic transformation and cyclic stability of elastocaloric effect in Ni-Mn-Sn magnetic shape memory alloys. Journal of Materials Research and Technology, 2022, 19, 4998-5007.

9. W Y Gui, C Zhong, J Y Gu, Y H Ding, X M Wang, T Wu, Y F Liang, J Y Qin, Y H Qu, J P Lin. Laser-clad Inconel 625 coatings on Q245R structure steel: microstructure, wear and corrosion resistance. npj Materials Degradation, 2022 6, 37.

10. W Y Gui, Y F Liang, J Y Qin, Y S Wang, J P Lin. Fluorine Effect for Improving Oxidation Resistance of Ti-45Al-8.5Nb Alloy at 1000°C. Materials 2022, 15(8), 2767.

11. P Zhang, W Y Gui, M Jiang, B L Luan. Influences of High-Basicity High-Alumina Refining Slags on the Cleanliness and Control of Non-metallic Inclusions in Inconel 625 Superalloy. Metallurgical and Materials Transactions A. 2022, 53, 2259–2269.

12. C C Sun, W Y Gui, J Lu, L Xie, Y D Wu. Comparison of the Deposition Process for Metallic and MG Coatings Using Cold Spraying. Journal of Thermal Spray Technology, 2022, 31, 1155–1172.

13. W Y Gui, Z J Shi, Y Zhang, Y F Liang, J Y Qin, Y L Wang, J P Lin, B L Luan. Ti-40Al-10Nb-10Cr Porous Microfiltration Membrane with Hierarchical Pore Structure for Particulate Matter Capturing from High-Temperature Flue Gas. Membranes, 2022, 12, 104.

14. T Wu, Y X Chen, S Q Shi, M T Wu, Wanyuan Gui (通讯作者), Y Y Tan, J H Li, Y Wu. Effects of W alloying on the lattice distortion and wear behavior of laser cladding AlCoCrFeNiWx high-entropy-alloy coatings. Materials, 2021, 14(18): 5450.

15. W Y Gui, J R Liu, X P Song, H Zhang, J P Lin, B L Luan. A new microfiltration membrane with three-dimensional reticular architecture for Nano-pollutants removal from wastewater. Progress in Natural Science: Materials International, 2021, 31(3): 414-419.

16. W Y Gui, Y F Liang, D Dong, J P Lin. FeAl/Al2O3 Porous Composite Microfiltration Membrane for Highly Efficiency High-Temperature Particulate Matter Capturing. Journal of Porous Materials, 2021, 28: 955-961.

17. W Y Gui, Y H Qu, H Zhang, J P Lin. Cathode electrolytic plasma deposition of (Al0.9Cr0.1)2O3/γ-Al2O3 composite coatings onto Ti45Al8.5Nb0.1Y0.2W alloys for high-temperature applications. Materialia, 2021, 15:101002.

18. W Y Gui, Y H Qu, Y F Liang, Yanli Wang, Hui Zhang, Benli Luan, J P Lin. High Efficiency Hierarchical Porous Composite Microfiltration Membrane for High-Temperature Particulate Matter Capturing. npj Materials Degradation, 2021, 5(1): 1.

19. C Fang, W Y Gui (通讯作者), J P Lin. Slow-Growing Titanium Dioxide on Ti-48Al Porous Alloy Mediated by Nb and Cr Addition: Perspective via Local Metal–Oxygen Bonding Strength. Journal of Materials Engineering and Performance, 2020, 29: 1558-1566.

20. W Y Gui, J P Lin, M D Liu, Y H Qu, Y C Wang, Y F Liang. Effects of Nano-NiO Addition on the Microstructure and Corrosion Properties of High Nb-TiAl Alloy. Journal of Alloys and Compounds, 2019, 782: 973-980.

21. W Y Gui, J P Lin, J R Liang, Y H Qu, Y C Guo, K Lv, Hui Zhang. Micro-/Nano-Dual-Scale Porous Composite Membranes for the Separation of Nanopollutants from Water. ACS Applied Nano Materials, 2019, 2: 806−811.

22. W Y Gui, J P Lin, Y F Liang, Y H Qu, L Q Zhang, H Zhang, X C Li. A Two-step Strategy for High-efficiency Fluorescent Dye Removal from Wastewater. npj Clean Water, 2019, 2: 16-24.

23. W Y Gui, Y F Liang, G J Hao, J P Lin, D Y Sun, M D Liu, C Liu, H Zhang. High Nb-TiAl-based Porous Composite with Hierarchical Micro-pore Structure for High Temperature Applications. Journal of Alloys and Compounds, 2018, 744: 463-469.

24. Y H Qu, D Y Cong, S H Li, W Y Gui, Z H Nie, M H Zhang, Y Ren, Y D Wang. Simultaneously Achieved Large Reversible Elastocaloric and Magnetocaloric Effects and Their Coupling in a Magnetic Shape Memory Alloy. Acta Materialia, 2018, 1: 41-55.

25. F Cheng, S S Li, W Y Gui, J P Lin. Surface Modification of Ti-45Al-8.5Nb Alloys by Microarc Oxidation to Improve High-temperature Oxidation Resistance. Progress in Natural Science: Materials International, 2018, 28: 386-390.

26. C Fang, W Y Gui, J P Lin. Surface Midification of Q195 Structure Carbon Steel by Electrolytic Plasma Processing. Metals, 2018, 8: 831-841.

27. W Y Gui, J P Lin, G J Hao, Y H Qu, Z P Jiang, F Cheng, Y F Liang, H Zhang. Effect of Electrolytic Plasma Processing on the Removal of Surface Scale for Fe6.5Si Alloy. ChemistrySelect, 2017, 2:1158-1162.

28. W Y Gui, J P Lin, G J Hao, Y H Qu, Y F Liang, H Zhang. Electrolytic Plasma Processing-an Innovative Treatment for Surface Modification of 304 Stainless Steel. Scientific Reports, 2017, 7: 308-315.

29. Y H Qu, D Y Cong, Z Chen, W Y Gui, X M Sun, S H Li, L Ma, Y D Wang. Large and Reversible Inverse Magnetocaloric Effect in Ni48.1Co2.9Mn35.0In14.0 Metamagnetic Shape Memory Microwire. Applied Physics Letters, 2017, 111: 192412.1-192412.5.

30. Y H Qu, D Y Cong, X M Sun, Z H Nie, W Y Gui, R G Li, Y Ren, Y D Wang. Giant and Reversible Room-temperature Magnetocaloric Effect in Ti-doped Ni-Co-Mn-Sn Magnetic Shape Memory Alloys. Acta Materialia, 2017, 134: 236-248.

31. W Y Gui, G J Hao, Y F Liang, F Li, X Liu, J P Lin. Surface Modification by Electrolytic Plasma Processing for High Nb-TiAl Alloys. Applied Surface Science, 2016, 389: 1161-1168.

32. W Y Gui, J P Lin, G J Hao, Y F Liang, W Q Wang, Y Q Wen. Light-Triggered Drug Release Platform Based on Superhydrophobicity of Mesoporous Silica Nanoparticles. Nanoscience and Nanotechnology Letters, 2016, 8: 428-433.

33. W Y Gui, W Q Wang, X Y Jiao, L F Chen, Y Q Wen, X J Zhang. Dual-Cargo Selectively Controlled Release Based on a pH-Responsive Mesoporous Silica System. ChemPhysChem, 2015, 16, 607-613.

l Patents

桂万元, 林均品, 栾本利. 具有氧化膜的TiAl多孔合金及其制备方法、应用. 授 权 公 告 号:CN 114182318 B.

Preparation method of TiAl porous alloy with oxide film and its application